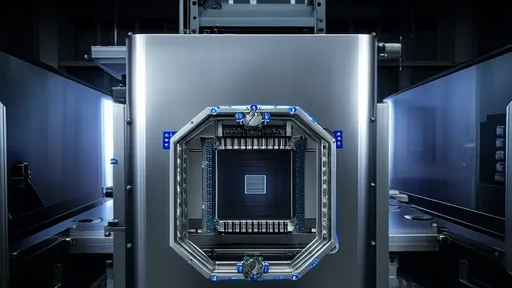

The relentless pursuit of computing power has led chip designers into the third dimension, where stacked architectures promise unprecedented performance but confront engineers with formidable thermal challenges. As semiconductor manufacturers push the boundaries of 3D integration, microfluidic cooling has emerged as a potential game-changer for managing the intense heat generated within these densely packed structures.

Thermal bottlenecks in 3D chip design have become the critical limiting factor in next-generation semiconductor development. Unlike traditional planar chips that dissipate heat across a large surface area, vertically integrated circuits concentrate power density in ways that overwhelm conventional cooling solutions. The thermal resistance between stacked layers creates hotspots that can degrade performance, reduce reliability, and in extreme cases, cause catastrophic failure.

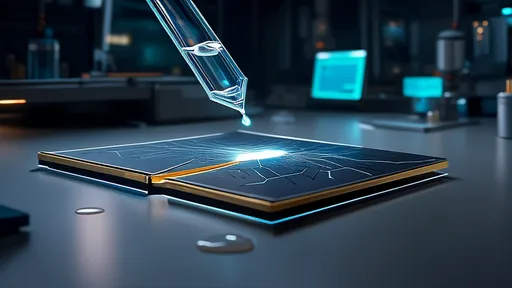

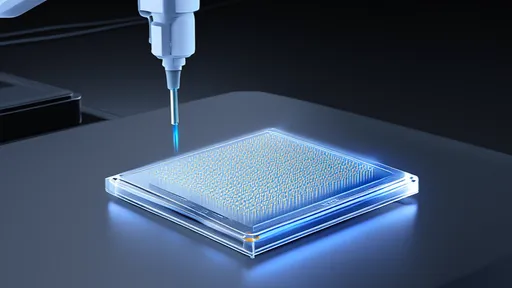

Researchers at leading semiconductor firms and academic institutions are now turning to microfluidic thermal simulation as an essential tool for designing viable 3D chips. These sophisticated modeling techniques allow engineers to predict heat distribution and fluid dynamics at microscopic scales before committing to expensive fabrication processes. By simulating how coolant flows through microchannels etched directly into silicon interposers or between chip layers, designers can optimize both the thermal performance and structural integrity of 3D architectures.

The complexity of these simulations stems from the need to model multiple physical phenomena simultaneously. Computational fluid dynamics (CFD) must account for the unique behavior of fluids at micron scales, where surface tension and viscous forces dominate over inertial effects. These fluid models must then couple with thermal simulations that track heat generation from billions of transistors and its conduction through diverse materials with varying thermal properties.

Recent breakthroughs in simulation algorithms have dramatically improved the accuracy and efficiency of these analyses. Novel meshing techniques can now handle the extreme aspect ratios of microfluidic channels that might be hundreds of microns long but only tens of microns wide. Adaptive time-stepping methods help resolve the rapid temperature fluctuations that occur when coolant first encounters high-power regions. Meanwhile, machine learning acceleration enables parameter exploration that would be computationally prohibitive with traditional approaches.

Experimental validation has kept pace with these simulation advances. At the University of California, Berkeley, researchers have developed benchmark cases comparing simulated and measured temperatures in test chips with embedded microchannels. Their work demonstrates agreement within 5% for steady-state conditions and 10% for transient scenarios - remarkable accuracy given the complexity of the physics involved. Such validation gives chip designers confidence to rely on simulation results during the critical early phases of product development.

The semiconductor industry's roadmap suggests microfluidic cooling will become indispensable for high-performance 3D chips expected to reach power densities exceeding 1 kW/cm² by 2025. Current air-cooled solutions struggle to handle more than 100 W/cm², while even advanced heat sinks and vapor chambers top out around 500 W/cm². Only direct liquid cooling at the microscale can potentially manage the thermal loads of future processors combining logic, memory, and accelerators in 3D configurations.

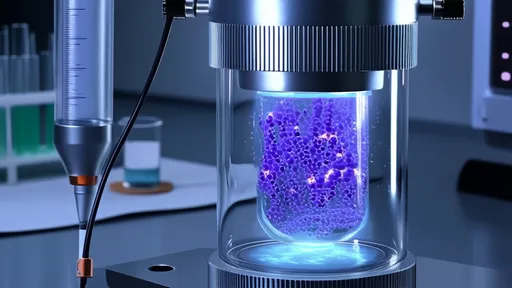

Several implementation approaches have emerged from research labs to production facilities. Passive microfluidic systems rely on carefully designed channel geometries to create capillary action or other surface-force-driven flows. These avoid the reliability concerns of mechanical pumps but provide limited cooling capacity. More aggressive designs incorporate electrokinetic or magnetohydrodynamic pumps that can generate substantial pressure without moving parts. The most powerful solutions integrate micropumps directly into the chip package, though these add complexity and potential failure modes.

Material innovations are expanding the design space for microfluidic cooling. Silicon remains the dominant substrate due to its excellent thermal conductivity and compatibility with semiconductor manufacturing processes. However, researchers are experimenting with diamond heat spreaders, graphene-coated channels, and metal-organic frameworks that offer superior thermal properties. These advanced materials often require specialized simulation approaches to account for their anisotropic behavior or unconventional interfacial properties.

The thermal benefits of microfluidic cooling extend beyond mere temperature reduction. By maintaining more uniform thermal profiles across 3D chips, these systems enable higher sustained clock speeds and reduce thermally induced stress that can degrade reliability over time. Some designs even exploit the temperature-dependent behavior of certain transistors to create performance gradients that optimize overall chip efficiency - an approach that demands exceptionally precise thermal control.

Commercial adoption faces several remaining challenges. Manufacturing yield remains a concern when adding intricate fluidic networks to already complex 3D chip stacks. The potential for clogging in micron-scale channels requires robust filtration systems and possibly self-cleaning mechanisms. Long-term reliability data is still being gathered for various microfluidic approaches, particularly those involving novel materials or active pumping mechanisms.

Looking ahead, the convergence of 3D chip design and microfluidic cooling appears inevitable for high-performance computing applications. Simulation tools will play an increasingly vital role in navigating the complex tradeoffs between thermal performance, power efficiency, structural integrity, and manufacturability. As these technologies mature, we may see microfluidic thermal management trickle down from supercomputers and data center accelerators to consumer devices, enabling new generations of compact yet extraordinarily powerful electronics.

The next five years will likely determine whether microfluidic cooling becomes a mainstream solution or remains confined to niche applications. Much depends on continued improvements in simulation accuracy, manufacturing techniques, and system-level integration. What's certain is that thermal considerations will no longer be an afterthought in chip design, but rather a primary driver of architecture decisions from the earliest planning stages.

For the semiconductor industry, mastering microfluidic thermal management represents both a formidable challenge and a tremendous opportunity. Companies that develop robust simulation-led design methodologies may gain significant competitive advantages in bringing high-performance 3D chips to market. Meanwhile, the scientific community continues to uncover new physical phenomena at the intersection of fluid dynamics, heat transfer, and nanoscale engineering - discoveries that will undoubtedly shape the next generation of thermal simulation tools and cooling solutions.

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025