The relentless march of technology has brought computing power to the farthest reaches of our industrial and environmental landscapes. Edge devices, those hardy sentinels of data collection and processing, now operate in conditions that would cripple lesser machines. Among the most insidious threats they face is salt spray corrosion – a silent destroyer that creeps into circuits and connectors, leaving failure in its wake.

Salt spray corrosion occurs when airborne salinity deposits on metal surfaces, initiating electrochemical reactions that eat away at materials over time. For edge devices deployed in coastal regions, offshore installations, or maritime applications, this isn’t a hypothetical risk – it’s a daily assault. The consequences range from intermittent sensor failures to catastrophic system breakdowns, often with costly downtime and data gaps.

Material science has risen to this challenge with innovative solutions. Traditional stainless steel enclosures, while effective against general moisture, often fall short against prolonged salt exposure. Recent advancements have seen the adoption of superalloys incorporating nickel, chromium, and molybdenum in precise ratios. These formulations create passive oxide layers that self-heal when scratched, providing continuous protection even in abrasive saline environments.

Beyond metals, composite materials are making waves in corrosion-resistant designs. Fiber-reinforced polymers infused with nano-ceramic particles create enclosures that are simultaneously lightweight and impervious to salt penetration. The manufacturing process allows for seamless designs that eliminate crevices where corrosive elements might accumulate – a critical advantage over traditional welded metal casings.

Connectors represent the Achilles’ heel of many edge devices. Even the most robust enclosure proves worthless if corrosion sneaks in through pin connectors or cable glands. Leading manufacturers now employ gold-plated contacts with hermetic sealing techniques originally developed for aerospace applications. Some have gone further, developing contactless power and data transfer systems that eliminate physical connectors altogether in favor of inductive coupling through sealed barriers.

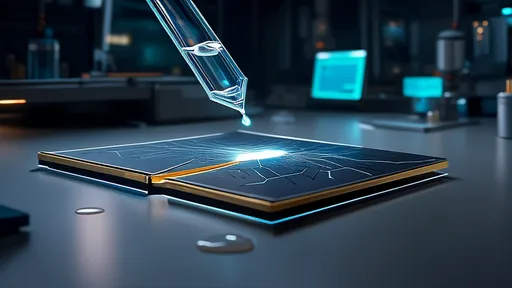

The protective measures continue at the circuit board level. Conformal coatings have evolved from simple acrylic sprays to sophisticated multilayer applications. Modern coatings combine silicone’s flexibility with polyurethane’s chemical resistance, often with a final layer of parylene that measures just microns thick yet provides an impenetrable moisture barrier. These coatings don’t just protect against salt spray – they withstand thermal cycling that could otherwise cause delamination.

Design philosophy plays an equally crucial role in combating salt spray damage. The best corrosion protection begins with recognizing that no barrier is perfect. Progressive manufacturers now design with controlled corrosion paths – sacrificial anodes and deliberate weak points that channel degradation away from critical components. This approach, borrowed from marine engineering, extends functional lifetimes dramatically while maintaining serviceability.

Testing standards have had to evolve alongside these technological advancements. Where salt spray testing once involved simple exposure chambers, modern qualification processes now combine cyclic corrosion testing with real-world environmental simulations. Devices might undergo temperature shocks from -40°C to 85°C while being bombarded with salt fog, followed by vibration sequences that test coating adhesion under stress. Only those that emerge functional after weeks of such abuse earn certification for harsh marine environments.

Maintenance strategies form the final layer of defense. Even the most resilient edge devices benefit from intelligent monitoring of corrosion progression. Some systems now incorporate corrosion rate sensors that measure metal loss in real-time, while others use impedance spectroscopy to detect coating breakdown before it reaches critical levels. This data allows for predictive maintenance, replacing components during scheduled downtime rather than after catastrophic failures.

The battle against salt spray corrosion represents one of the quiet triumphs of materials engineering. As edge computing pushes further into hostile environments, the solutions developed today will form the foundation for tomorrow’s industrial IoT revolution. From offshore wind farms to tropical research stations, these protected devices continue gathering data where others would simply surrender to the elements.

Looking ahead, researchers are exploring biologically inspired protections. Some marine organisms have evolved molecular-scale corrosion inhibitors that could be replicated in synthetic coatings. Other teams are developing self-healing polymers that release protective compounds when scratched. What remains constant is the understanding that in the harsh intersection of technology and nature, robust design isn’t optional – it’s the price of reliable operation.

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025