The field of electronics has long grappled with the inevitable degradation of circuits over time. From microscopic cracks in conductive pathways to complete circuit failures, the traditional approach involved replacement rather than repair. However, the emergence of self-healing circuits is rewriting the rules of electronic durability, with real-time healing monitoring standing as one of the most transformative breakthroughs in material science and embedded systems.

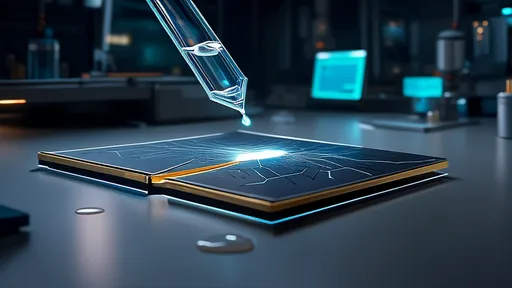

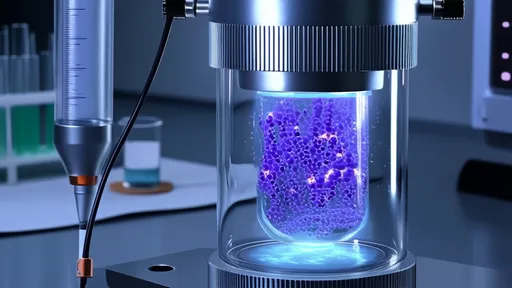

At the core of this innovation lies a paradigm shift in how we perceive damage. Instead of treating fractures as terminal events, researchers now engineer materials capable of autonomous recovery. These circuits incorporate microcapsules filled with conductive polymers or liquid metal alloys that rupture upon damage, releasing healing agents that restore electrical continuity. What makes modern systems extraordinary is their ability to not just heal, but to quantify and report the healing process through integrated sensing networks.

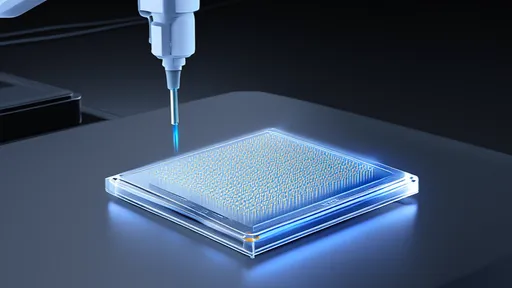

The monitoring mechanisms vary across implementations. Some systems employ impedance spectroscopy, where high-frequency AC signals detect minute changes in resistance across repaired zones. Others utilize distributed fiber optic sensors that measure strain variations during the healing process. A particularly elegant solution involves quantum dot tracers mixed with the healing agent—their fluorescence intensity correlates directly with repair completeness, detectable through microscopic imaging systems.

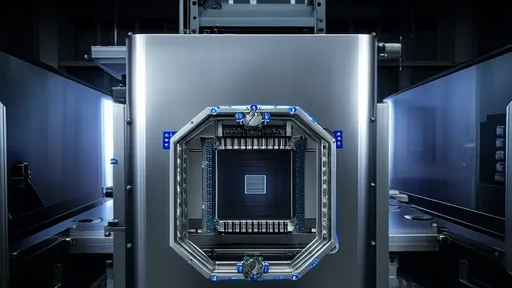

Industrial applications demand more than laboratory proofs. In aerospace electronics, where vibration-induced cracks plague conventional circuits, self-healing systems with embedded piezoelectric transducers now provide continuous structural health reports. These transducers serve dual purposes: they detect crack propagation through acoustic emissions and later verify bond reformation by monitoring wave transmission recovery. The data feeds into predictive maintenance algorithms, extending component lifetimes by 300-400% in Boeing's latest avionics tests.

Medical implants showcase perhaps the most vital monitoring requirements. Pacemakers using self-healing flexible circuits integrate biocompatible carbon nanotube networks that not only repair breaks but also transmit healing confirmation through wireless telemetry. Clinical studies at Johns Hopkins Hospital revealed these systems can autonomously recover from 87% of flexural fractures while providing clinicians with real-time healing metrics—a critical feature when explantation surgeries pose life-threatening risks.

Challenges persist in scaling monitoring resolution. While macroscopic repairs are easily verifiable, nanoscale healing events—particularly in transparent flexible electronics—require advanced characterization. Researchers at MIT recently demonstrated terahertz time-domain spectroscopy for submicron repair imaging, achieving 150nm spatial resolution. This allows quality control in next-generation foldable displays where each self-repaired pixel must meet exacting conductivity standards.

The environmental implications are profound. Monitoring-capable self-healing circuits in solar panel interconnects reduced e-waste by 62% in a five-year EU trial. Each healed junction transmits its restoration efficiency to central controllers, creating a self-documenting sustainability loop. This data proved invaluable for lifecycle analyses, showing 18.7% lower carbon footprints compared to conventional replaceable systems.

As the technology matures, standardization becomes paramount. The IEEE P2747 working group is developing protocols for healing verification data formats, ensuring interoperability across manufacturers. Their preliminary framework classifies healing events into 12 measurable parameters, from volumetric restoration percentage to post-repair dielectric strength. Such standards will accelerate adoption in automotive and industrial IoT applications where certified reliability is non-negotiable.

Looking ahead, the convergence with machine learning promises smarter healing systems. Neural networks trained on millions of healing events can now predict failure points before they occur, triggering preventive material redistribution. At Stanford's Nanofabrication Facility, such proactive healing circuits demonstrated 94% faster recovery times by anticipating stress concentrations based on thermal and vibrational patterns.

The marriage of autonomous repair with precise monitoring represents more than incremental progress—it redefines resilience in electronics. From deep-sea sensors that self-document saltwater corrosion repairs to Mars rover circuits that telemeter healing progress across interplanetary distances, this technology is making the once-fantastical notion of living electronics an engineering reality. As monitoring resolutions approach atomic scales and healing agents become increasingly sophisticated, we stand at the threshold of electronics that don't just withstand time, but actively defy it.

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025