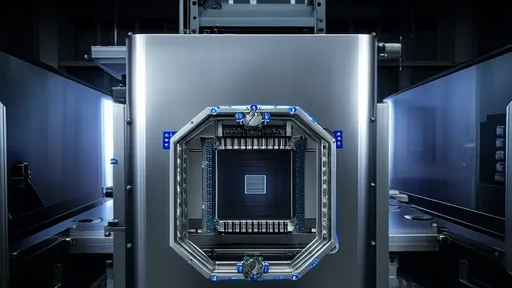

As data centers continue to push the boundaries of computational density and energy efficiency, immersion cooling has emerged as a game-changing technology. This innovative approach, where servers are fully submerged in dielectric fluid, offers superior thermal management compared to traditional air cooling. However, the long-term effectiveness of immersion cooling systems hinges on one often-overlooked factor: maintaining the purity of the cooling fluid.

The dielectric fluids used in immersion cooling serve as both thermal conductors and electrical insulators. When these fluids become contaminated, whether through particulate matter, moisture ingress, or chemical breakdown, their performance degrades significantly. Impurities can reduce the fluid's heat transfer capabilities, potentially leading to dangerous hotspots within servers. More alarmingly, contaminants may compromise the fluid's dielectric properties, increasing the risk of electrical shorts that could damage expensive hardware.

Several factors contribute to fluid contamination in immersion cooling systems. Outgassing from server components introduces various compounds into the fluid over time. The breakdown of gaskets, seals, and other materials submerged in the fluid can release particulate matter. Even minor leaks in the system can allow moisture or atmospheric gases to enter, while chemical reactions between the fluid and hardware components may produce unwanted byproducts. These contamination pathways underscore the need for robust purity maintenance protocols.

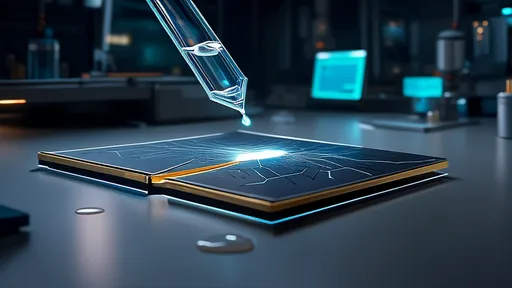

Modern immersion cooling systems employ multiple strategies to preserve fluid purity. Advanced filtration systems continuously remove particulate matter down to micron levels. Some systems incorporate moisture scavengers that actively remove water from the fluid, while others use gas purging techniques to eliminate dissolved gases. Regular fluid analysis through sampling and laboratory testing helps operators track fluid quality over time, allowing for proactive maintenance before problems escalate.

The consequences of neglecting fluid purity can be severe. Contaminated fluid often requires complete replacement, resulting in significant downtime and material costs. More critically, the reduced cooling efficiency from impure fluid can lead to thermal throttling of processors or even hardware failures. In extreme cases, fluid contamination has caused catastrophic electrical failures that damaged entire server racks. These risks make purity maintenance not just a matter of efficiency, but of system reliability and longevity.

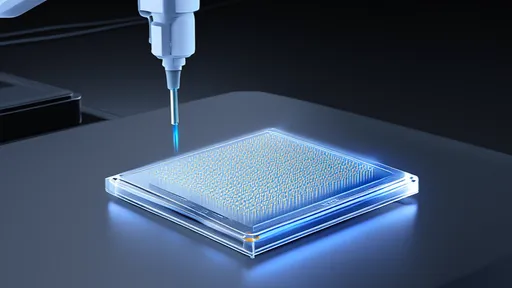

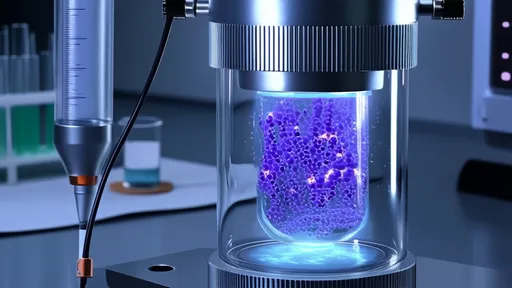

Emerging technologies promise to revolutionize how we maintain immersion cooling fluid purity. Smart sensors capable of real-time monitoring of fluid properties are becoming more sophisticated and affordable. Some manufacturers are developing self-cleaning fluids with nanoparticle additives that actively trap contaminants. Other innovations include photocatalytic purification systems that use light to break down organic contaminants directly in the fluid. These advancements may soon make fluid purity maintenance nearly autonomous.

Best practices for fluid purity maintenance begin with proper system design. Closed-loop systems with minimal exposure to atmosphere generally maintain purity better than open designs. Material compatibility is crucial - all wetted components must be carefully selected to minimize chemical interactions. Operational protocols should include regular fluid testing, immediate leak remediation, and strict procedures for any system opening that might introduce contaminants. Perhaps most importantly, staff training ensures that all personnel understand the critical role of fluid purity in system performance.

Looking ahead, as immersion cooling becomes more prevalent in edge computing and high-performance computing applications, maintaining fluid purity in diverse environments will present new challenges. Systems deployed in harsh industrial settings or remote locations may face greater contamination risks. The industry is responding with more robust filtration options and remote monitoring capabilities. Meanwhile, research into new dielectric fluid formulations aims to create fluids that are inherently more resistant to contamination while maintaining excellent thermal and dielectric properties.

The evolution of immersion cooling technology continues to accelerate, but one principle remains constant: the purity of the cooling fluid is fundamental to system performance, reliability, and total cost of ownership. As data center operators increasingly adopt immersion cooling, those who prioritize fluid purity maintenance will reap the greatest benefits in terms of energy efficiency, hardware lifespan, and operational stability. In this cutting-edge cooling paradigm, the old adage holds true - sometimes the most advanced solutions depend on maintaining the simplest things perfectly.

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025